Ho. Li. Crap... From the Seattle, WA FOX News affiliate:

Washington scientist admits faking steel-test results for Navy submarines

A metallurgist in Washington state pleaded guilty to fraud Monday after she spent decades faking the results of strength tests on steel that was being used to make U.S. Navy submarines.

Elaine Marie Thomas, 67, of Auburn, Washington, was the director of metallurgy at a foundry in Tacoma that supplied steel castings used by Navy contractors Electric Boat and Newport News Shipbuilding to make submarine hulls.

From 1985 through 2017, Thomas falsified the results of strength and toughness tests for at least 240 productions of steel — about half the steel the foundry produced for the Navy, according to her plea agreement, filed Monday in U.S. District Court in Tacoma. The tests were intended to show that the steel would not fail in a collision or in certain "wartime scenarios," the Justice Department said.

And this:

She suggested that in some cases she changed the tests to passing grades because she thought it was "stupid" that the Navy required the tests to be conducted at negative-100 degrees Fahrenheit.

The current operating theory of why the Titanic sank is that the metal in its rivets became brittle at cold temperatures. They were fine in the shipyard - passed every test with flying colors but they would snap with a clean break when chilled: here, here, here and here. Testing at —100° is a perfect way to accentuate any potential issues with the batch of steel.

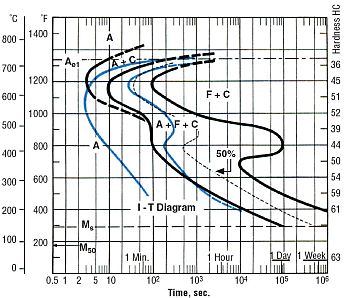

I do blacksmithing and have studied a lot about metal heat treating. It is not a trivial subject. Fascinating but not trivial. For example, here is a chart that an engineer would use to determine the proper heat treatment of a specific steel alloy:

You are looking at Temperature and Time. The elements of the graph indicate the relative concentrations of Martensite, Austenite, Ferrite and Cementite in the crystaline structure. I am simplifying things greatly. There are also options for cryogenic treatment. And this is for just one alloy with a specific chemical composition. Change anything and you have to develop an entirely new chart and an entirely new heat treatment protocol. Also note that some transitions have to happen over a few seconds at a specific temperature. Other transitions require several hours or maybe a week at a specific temperature. You do not simply heat it red hot and plunge it into a bucket of water or oil. At least, not for a submarine hull...

What she did is unconscionable.

Leave a comment